CNC Turning Service

Top CNC Turning Service Provider in China

Hopeful's CNC Turning Service Solution

Precision Machining

Every CNC-turned component is produced to remarkably precise tolerances of ±0.005mm to ±0.01mm, delivering superior fit.

Automation and AI Integration

Sustainability and Energy Efficiency

Multi-Axis Capabilities

Versatility

Reliability

Advantages of CNC machined Turning

- Improved Efficiency: With automation in CNC turning, intervention is minimal which decreases production time and errors.

- Safety: CNC turning is safer thanks to automation reducing human involvement.

- Repeatability: CNC turning processes enable the production of parts with consistent quality even at large production rates.

- Flexibility: With the aid of programmed parameters, these machines swiftly adjust to different production tasks.

- Faster Production: The procedure enables the quick manufacturing of components thereby increasing throughput while minimizing lead times.

Advantages of CNC machined Turning

- Material Selection: Consider parameters like intensity, heat-withstanding ability, abrasion resistance, and acceptance of coolant and lubricant oils.

- Mitigating Tolerance Risks: Determine design risks such as residual stresses or tool deflection that can impact the machining accuracy.

- Surface Finish: An adequate surface finish reduces frictional resistance, lessens wear, increases effectiveness, and improves visual appeal.

- Threading and Grooving:These features improve assembly and optimize the performance of a part through secure fastening and efficient surface transitions.

- Waste Reduction:The integration of eco-friendly techniques, such as recycling offcuts and improving the methods of machining, reduces waste.

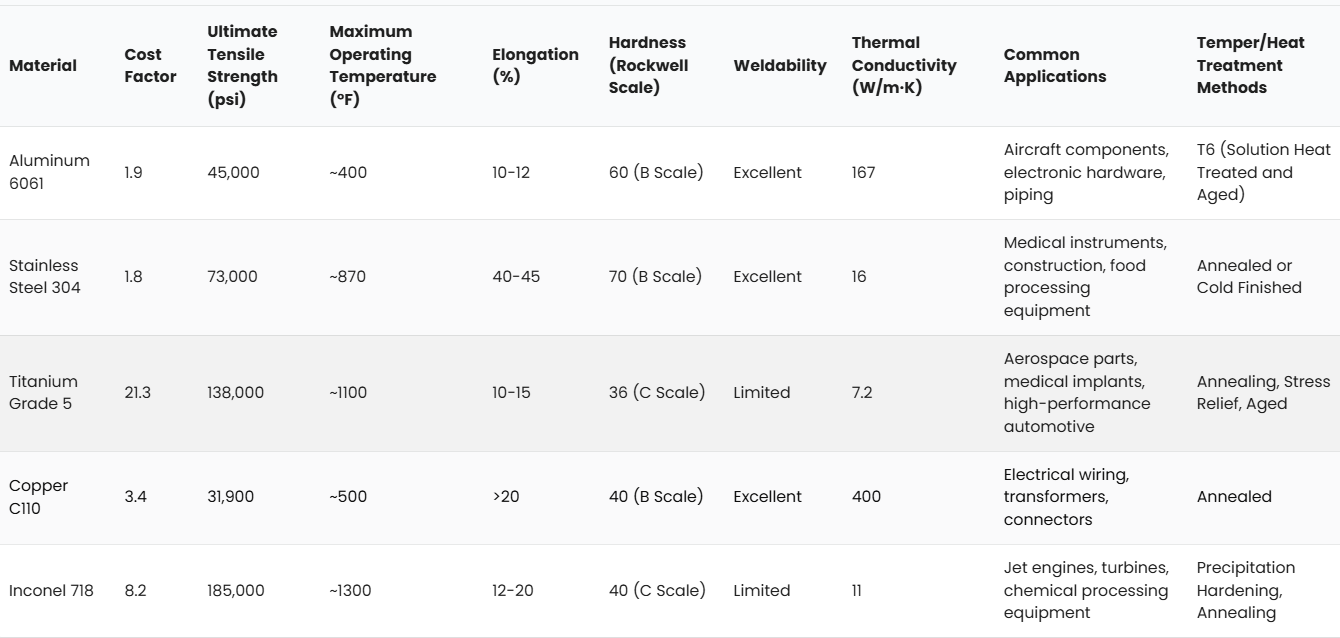

Compare Materials for Turning

✷ Applications of Turning Custom CNC Machining ✷

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Aerospace Industry

The aerospace industry employs custom CNC machining extensively for the production of critical components such as turbine blades, engines, and structural brackets.

Automotive Industry

Vehicle manufactures make use of CNC machining for the development of prototypes, engine parts, and even specialized elements like transmission cases and cylinder heads.

Defense and Military Equipment

Due to the accuracy and reliability from the CNC machining process, quality parts meant for defense applications such as firearms, communication systems, and missile systems are produced.

Tool and Die Manufacturing

The accurate custom CNC machining enables the proficient production of molds, dies, and jigs required in manufacturing of highly intricate designs.

Customized Consumer Products

Luxury watches, bicycle components and electronic gadgets are types of goods tailored and produced using CNC machining.

Medical Device Fabrication

CNC machining is greatly demanded in the manufacture of intricate medical tools and devices such as surgical blades, prosthetic limbs, and orthopedic bones.

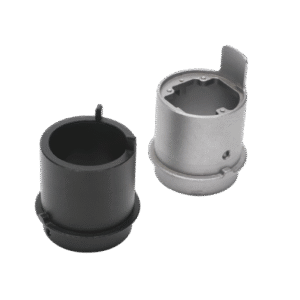

Gallery of CNC Machining Turning Parts Produced by Hopeful

Explore Hopeful’s CNC machinery turning parts, designed to provide exceptional durability and meet the highest standards for a wide range of industry applications.

Surface Finishes For CNC Machined Turning Parts

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Applies a layer of nickel-phosphorus alloy which enhances corrosion resistance and the hardness of the surface.

Offering a durable and colorful finish.

Enhances electrodeposition capabilities while improving aluminum component corrosion resistance.

Strengthens anti-corrosiveness of stainless steel by acid treating and removing free iron at the surface.

Provides corrosion protection by electro-galvanizing or hot dipping zinc onto steel surfaces.

Uses electricity to polish metal parts to a shiny, smooth surface.

Also called barrel finishing, it polishes parts by rotating them with abrasive media.

why choose Hopeful Factory's CNC Turning Service

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Applies a layer of nickel-phosphorus alloy which enhances corrosion resistance and the hardness of the surface.

Offering a durable and colorful finish.

Enhances electrodeposition capabilities while improving aluminum component corrosion resistance.

Strengthens anti-corrosiveness of stainless steel by acid treating and removing free iron at the surface.

Provides corrosion protection by electro-galvanizing or hot dipping zinc onto steel surfaces.

Uses electricity to polish metal parts to a shiny, smooth surface.

Also called barrel finishing, it polishes parts by rotating them with abrasive media.

Resources on China CNC Machining Services

- What is CNC Turning

- What is the principle of turning?

- What is CNC turning tools?

- What materials are used in CNC turning?

- What is the CNC turning process?

- What is the G-code and M code?

Related products provided by Kunshan Hopeful Metal Products Co.,Ltd

CNC Turning Service

Top CNC Turning Service Provider in China For high-precision CNC turning services in China, you can always rely on Hopeful/

Latest Blog Posts

Keep Yourself Updated With The Latest Inventions And Innovations By Reading Our Blog, As It Contains Professional Advice, Trends, And The Best Practices.

Hello world!

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

Related Topics About CNC Turning Service

One of the best designs for your animated number counter widget with a side separator.

Exporting country

Plant Area

Satisfied customer

Monthly output

Frequently Ask Questions

A: CNC turning service is a type of machining that utilizes a CNC lathe to carve out a workpiece into a turned part with great accuracy. Such services are offered for a variety of purposes, including prototyping and production in different materials, regardless of their metal or plastic composition.

A: The single most important machine in CNC turning is the CNC lathe, which, as the name suggests, cuts an object by spinning it. Other related equipment includes turning washes and CNC turning, which can perform additional features that are more sophisticated.

A: There are many factors that affect the surface finish of CNC parts, including the kind of tool used, cutting speed, feedrate, and the workpiece material. CNC turning surface finishes may be cut to the texture and smoothness required during the machining process based on these factors.

A: CNC turning services allow the application of close tolerances ranging usually within ±0.001 inches, although it depends greatly on machining process specifications alongside CNC machine capabilities.

A: Different sections, from automotive and aerospace to medical devices and consumable electronics, require precision CNC-turned parts. Such components are vital for industries where there’s a need for consistent precision and efficiency.

A: Absolutely, creating prototypes is one of the key areas where CNC turning services shine. Most companies that offer these machining services can create a prototype in a single day, which can then be tested and changed as needed, encouraging quick results from designs.

A: Today, turning on the CNC is most executed on materials like metals, such as aluminum and stainless steel, and polymer plastics and other alloys, but the materials depend on the properties and the planned use of the final parts.

A: The main difference is that during CNC turning the workpiece is rotated while the cutting tool is held stationary, which removes material and creates cylindrical shapes. While in CNC milling, the workpiece is kept stationary and is shaped by the rotating tools into finer details and plane designs.

A: CNC machines do possess turning capabilities that include the use of multi-axis lathes and live tooling for additional machining processes, handling of intricately designed parts, and other multi-axis turning options. These capabilities are useful in increasing the efficiency and productivity of the machining operation.